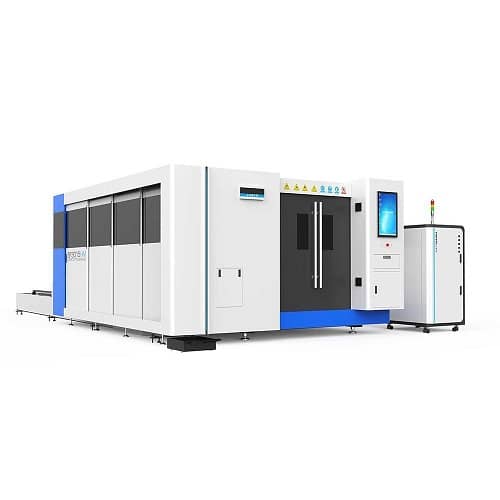

The laser beam is used to cut the material. The beam's intensity ensures that the cut does not alter the molecular structure of the object. No cracks or broken surfaces result. The Acrylic Laser Cutting tool is capable of cutting Plexiglass and Perspex as well as glass. It is simple and does not require any after-treatment.

Laser technology can be used to cut acrylic and glass with the best results. This method is faster and more efficient than traditional cutting methods and chips. The surface doesn't require any fixing or clamping because it is non-contact. Laser beam engraving gives you more precise results.

The computer controls all machines, so the user can change the design whenever he wants. This saves labour since a single person can control up to five machines. These laser machines are unique in that they use Carbon Dioxide gas for cutting. Laser cutting machines are accurate if they use CO2 correctly and with the correct quality.

Accuracy is essential for any task related to engraving or cutting acrylic glasses. Laser cutting is the best choice for fine work on acrylic surfaces. Laser cutting allows the user to simultaneously cut and engrave material using simple computer commands. The machine can produce fine designs, as well as photo engravings.

The laser cuts smoothly across the surface, creating the desired impact. To achieve the best effect, the laser cuts the inner edges and flame polishes them. This machine is designed to cut acrylic surfaces. It also has a full set of functions that can be used for delicate glass surfaces.