Image source: Google

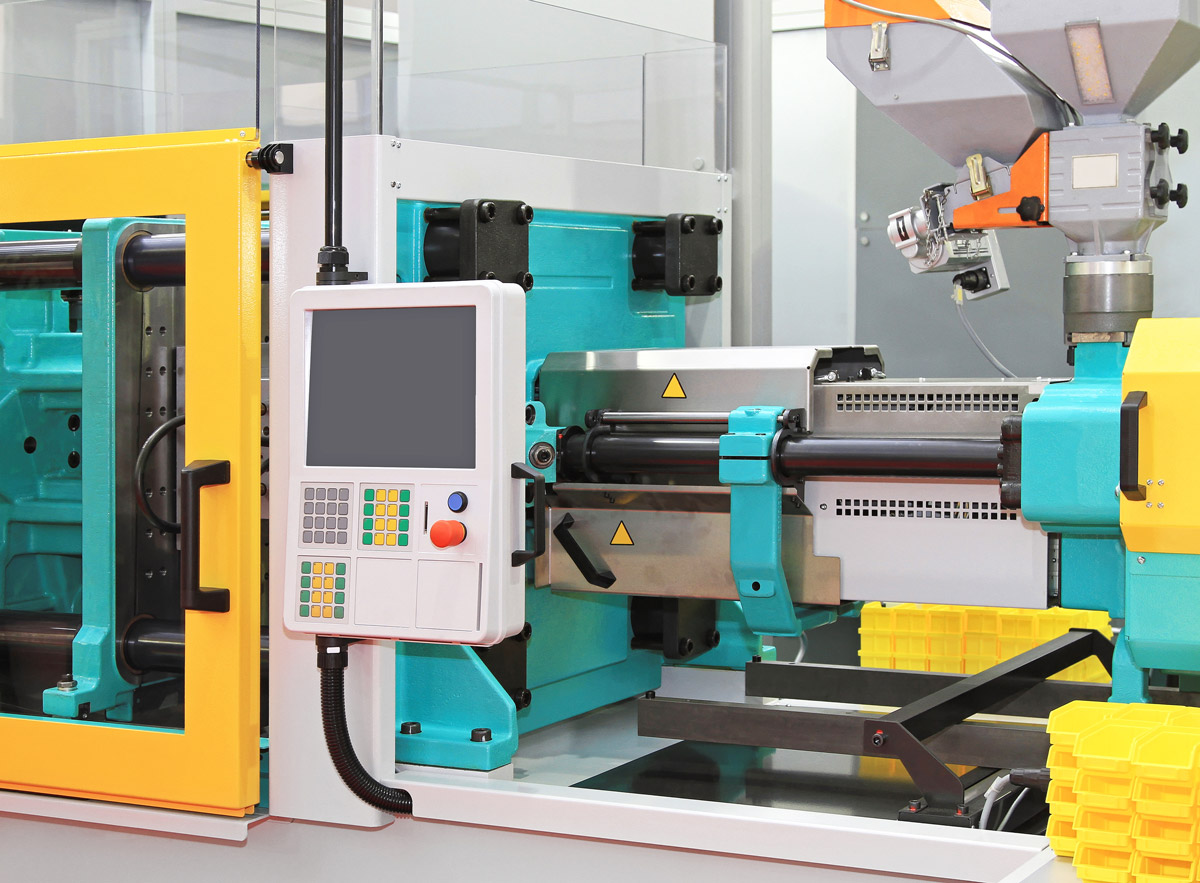

Injection molding suppliers have been at the forefront of revolutionizing the manufacturing industry, transforming the way products are designed, produced, and distributed across various industries. With advancements in technology and materials, injection molding has become a widely adopted manufacturing process that offers numerous benefits to businesses looking to streamline their production processes and reduce costs.

One of the key ways in which injection shaping suppliers are transforming industries is through the use of innovative materials that offer higher strength, durability, and flexibility. These materials, such as thermoplastics, thermosets, and elastomers, allow for the production of complex and intricate parts that would be difficult or impossible to create with traditional manufacturing methods. This enables businesses to create products that are lighter, more efficient, and more cost-effective, giving them a competitive edge in the market.

Moreover, injection molding suppliers are also leveraging cutting-edge technologies such as 3D printing, computer-aided design (CAD), and simulation software to optimize the design and production processes. By using these tools, manufacturers can create prototypes, test different designs, and make adjustments quickly and efficiently, reducing time-to-market and ensuring high-quality products. This level of precision and customization is revolutionizing the way products are developed and manufactured, leading to improved performance and customer satisfaction.

Another way in which injection molding suppliers are transforming industries is by embracing sustainable practices and environmentally friendly materials. With growing concerns about climate change and environmental impact, businesses are increasingly turning to eco-friendly solutions that minimize waste and reduce carbon footprint. Injection molding suppliers are responding to this demand by using biodegradable materials, recycling processes, and energy-efficient technologies to minimize environmental impact while maintaining high manufacturing standards.

Furthermore, injection molding suppliers are playing a crucial role in reshoring manufacturing operations back to domestic markets. With the rise of globalization and outsourcing, many businesses have moved their production facilities overseas in search of lower labor costs and cheaper resources. However, this trend is now shifting as businesses realize the risks and challenges associated with offshore manufacturing, such as supply chain disruptions, quality control issues, and intellectual property theft. Injection molding suppliers are helping businesses bring their manufacturing operations back home by providing reliable and cost-effective solutions that meet their production needs.

In conclusion, injection molding suppliers are transforming industries by driving advancements in materials, technologies, and practices that enhance product quality, reduce costs, and improve sustainability. By leveraging these innovations, businesses can stay ahead of the competition, meet customer demands, and navigate the challenges of the modern manufacturing landscape. As injection molding continues to evolve and expand, its impact on industries across the globe will only continue to grow, driving further innovation and growth in the manufacturing sector.